High-Precision SMT Reference – Precise, Robust, Calibratable

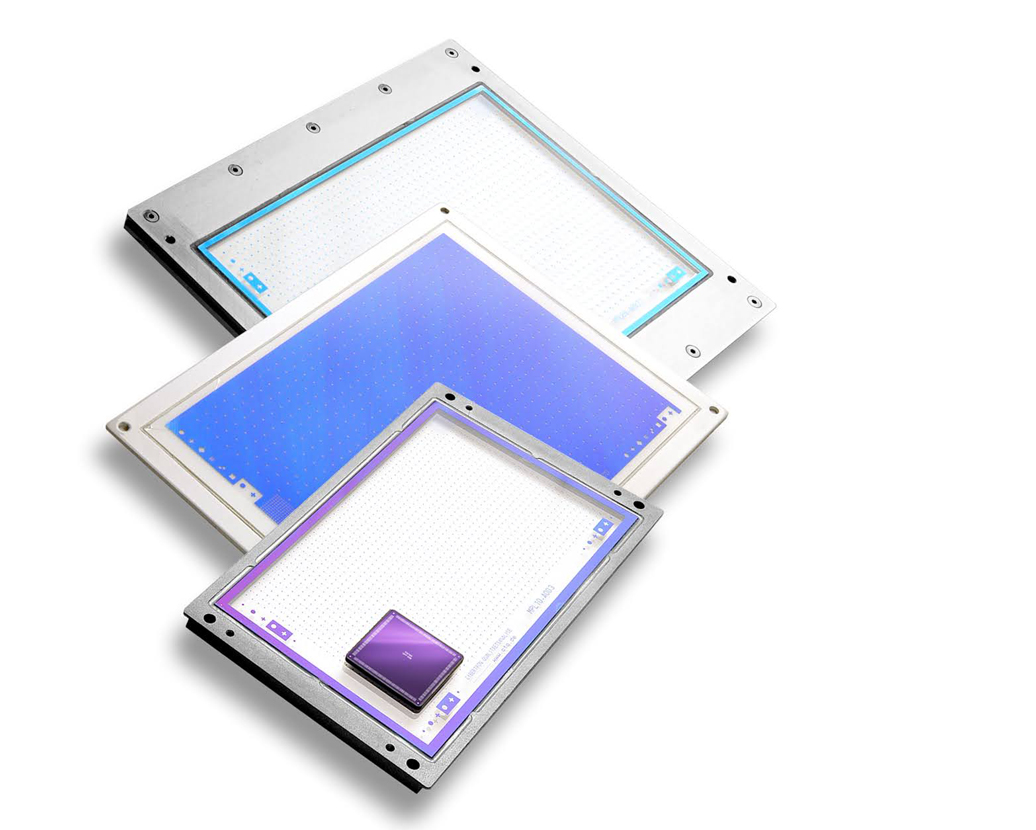

Measurement Plates – Precision for Your Process Validation with the CmController

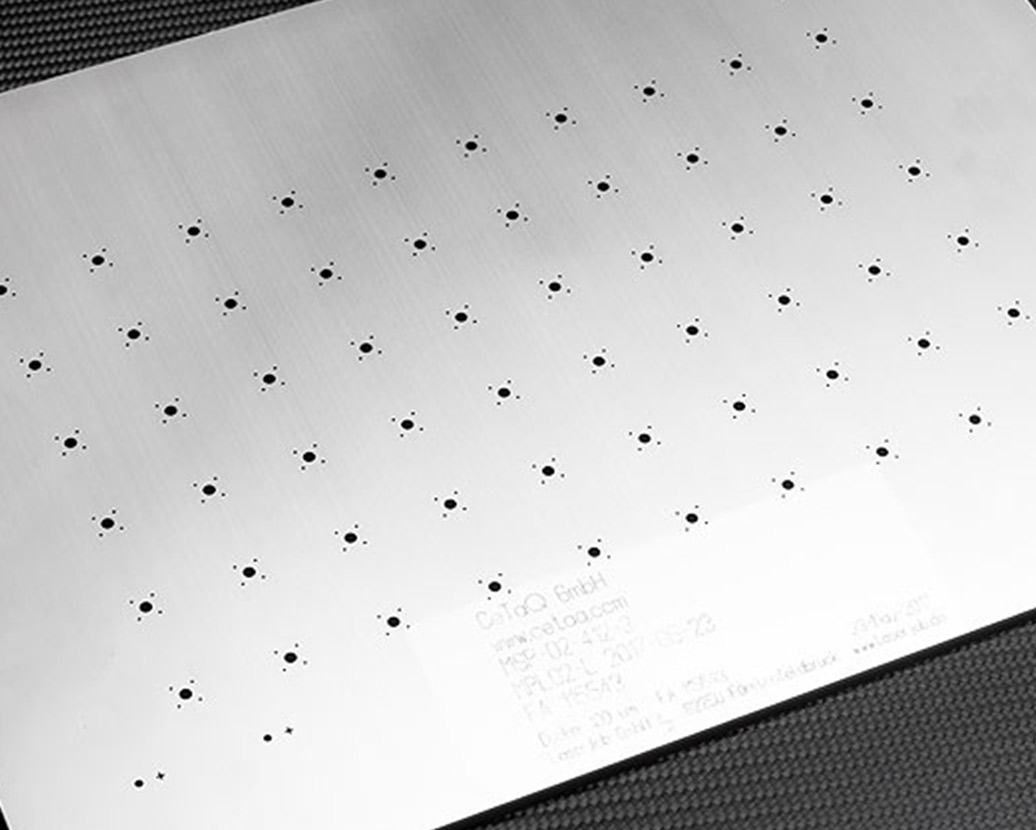

Instead of circuit boards, high-precision measurement plates with precisely etched fiducial marks are used. These pass through the system to be tested just like in a typical manufacturing process, thereby eliminating all deviations caused by production materials.

Eliminate Sources of Error, Measure Precisely, Master Audits

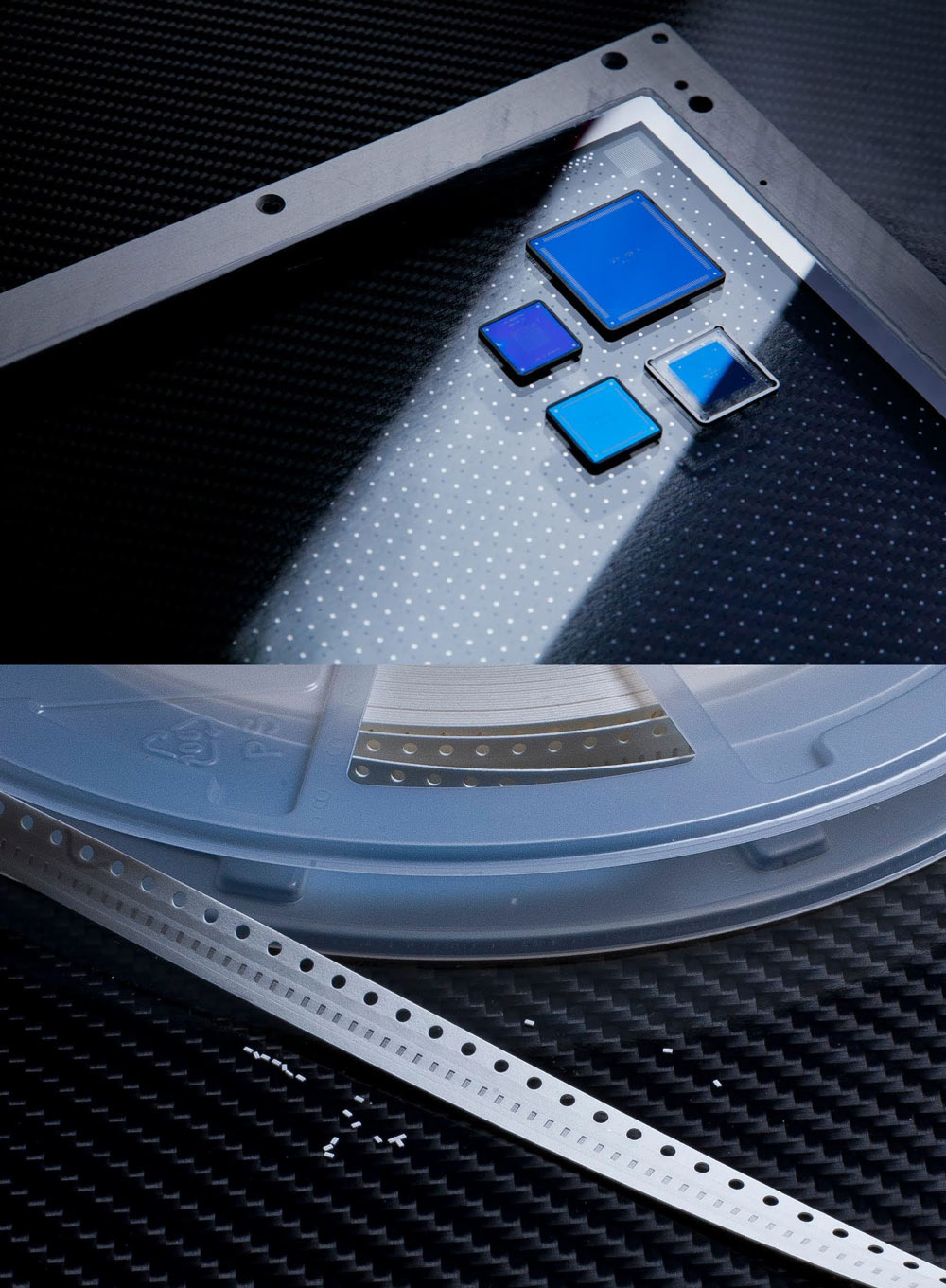

Reference Board for Laser Marking

It is a measurement plate specially developed for the validation of marking lasers. It is mechanically stable and robust against laser beams. Markings are made on a supplied, replaceable film.

Standard Measurement Plates

Measurement plates are the basis for measurements with the CmController. They are processed by SMT machines like a normal circuit board. The subsequent measurement compares the work result with the specifications.

Measurement Components

Measurement components are required for checking SMT pick-and-place machines. These are placed on one of our measurement plates, and their positions are measured with the CmController.

Technical details easily explained

Additional measurement points are applied to the measurement plates and glass components, which enable the measurement system (e.g., CmController) to determine the position of components, etc.

Components and circuit boards used in production often have very large tolerances. If these are used for measurements, the results will contain a mix of machine and component tolerances. Therefore, the tolerances of production components are eliminated by using precise, highly accurate replicas.

Common reference plates include: MPL02, MPL07, and MPL09. For special requirements, we also manufacture individual measurement standards.

- MPL02: 340×240 mm

- MPL09: 216×185 mm

- MPL07: 7”x4” (153.4 mm x 101.6mm)

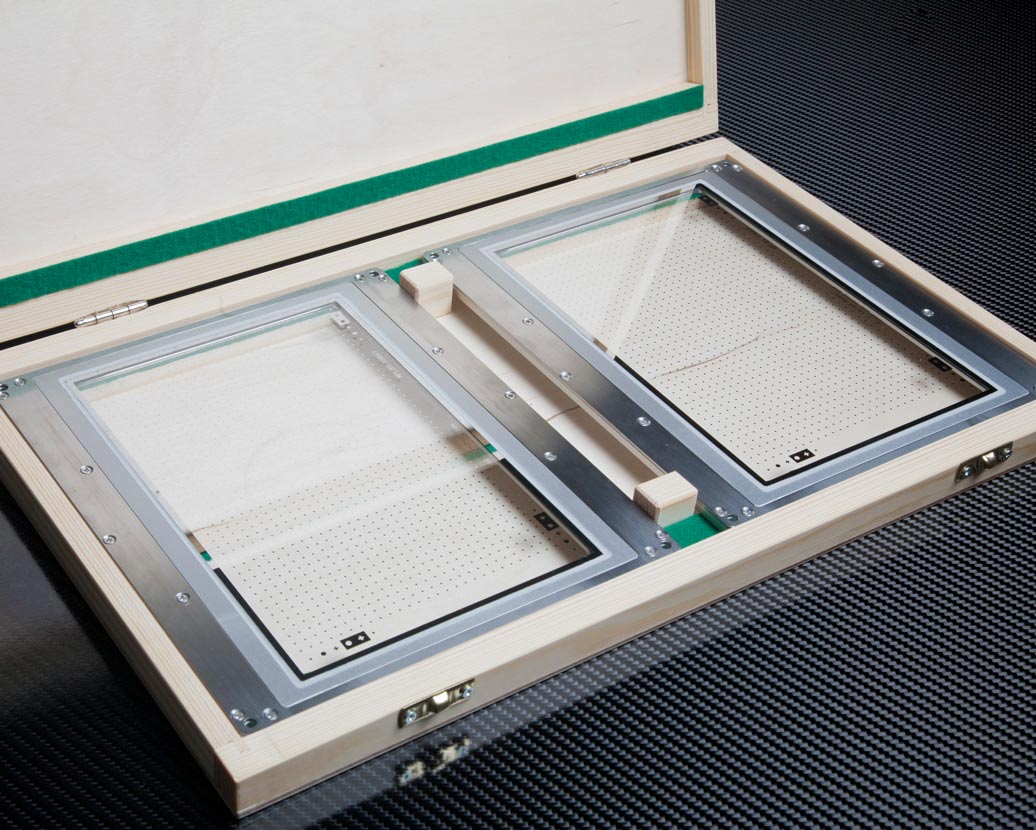

Yes – encapsulated in housings or frames, they can usually withstand falls from one meter without damage.

They are handled like normal SMT components and automatically processed by production machines.

-

Material: High-precision glass, embedded in frame/housing

-

Reference Types: MPL02, MPL07, MPL09 (standard), individual special cases possible

-

Special Features: Glass integrated into plastic housing, pin structure, glass-based conductor simulators

-

Protection: Protection against breakage, robust up to a 1 m drop

-

Patent: Design and construction features are patent protected

Technical Details

They prevent costly rework, ensure audit capability, and provide reliable quality management throughout the line.

Flawless identification is mandatory in many industries, as it ensures quality standards and meets the requirements of audits and certifications.

Precise measurements of accuracy and repeatability reveal even the smallest deviations before they impact production.

Often, these are offsets or inaccurate markings that affect the traceability and quality of the products.