Machine vs. Process Capability Analysis

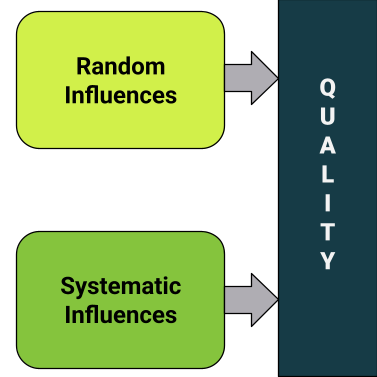

Understanding the difference between Machine Capability Analysis (MFU) and Process Capability Analysis (PFU) is fundamental for evaluating the performance of manufacturing processes. The essential difference lies in the period over which data is collected, and consequently, in the influencing variables that are deliberately included in or excluded from the analysis. This distinction allows for a more nuanced understanding of the inherent capabilities of a process compared to its actual performance.

Machine Capability (Short-Term Analysis)

Focus and Purpose:

Short-term analysis, often referred to as machine capability, serves to assess the inherent potential and precision of a single machine or a specific process step under controlled conditions. The primary goal is to determine whether the equipment itself is capable of consistently producing parts within the specified tolerances, minimizing external disturbances. It answers the question: Can this machine produce good parts if all external factors are perfect or perfectly controlled?

Methodology and Duration:

- Controlled Environment: Data collection for short-term studies takes place in a carefully controlled environment. This means that influences from human operators, fluctuations in raw material batches, environmental influences (temperature, humidity), and even machine warm-up effects are minimized.

- Short Duration of Data Collection: To achieve this controlled state, data is collected over a very short, concentrated period. Typically, this involves processing a relatively small, consecutive batch of parts, for example, 50 to 100 pieces. The short duration ensures that conditions remain as stable and consistent as possible, effectively isolating the machine’s performance.

- Consecutive Production: The parts are often produced consecutively without interruption to further reduce the likelihood of external factors influencing the results.

Influencing Variables:

- Focus on Machine-Internal Variations: The analysis primarily captures the common causes of variations that originate from the machine itself. This includes factors such as machine wear, tool deflection, vibrations, and the precision of the mechanical and control systems. These are the random, machine-internal influences that are always present in a stable process.

- Exclusion of External Influences: Crucially, short-term analysis deliberately excludes or minimizes variations typically caused by the following factors:

- Different operators (skills, differences in settings)

- Different material batches (material properties, dimensions)

- Environmental conditions (temperature, humidity, dust)

- Machine warm-up or wear over time

- Tool changes or adjustments during longer run times

Terminology:

- Machine Capability Indices: The results of short-term studies are commonly expressed using machine capability indices such as (machine capability) and (machine capability index, which also considers centering in relation to the specification limits). These indices provide a quantitative measure of the machine’s ability to meet specifications under ideal conditions.

Practical Application:

- Equipment Acceptance: Used during the installation and commissioning of new machines to verify that they meet the manufacturer’s specifications and can inherently produce within tolerances.

- Process Release: To confirm that a specific setup on a machine is optimized and functional before a production run is started.

- Troubleshooting: To determine whether a quality problem is due to the fundamental performance of the machine or to other process-related factors.

Process Capability/Process Performance (Long-Term Analysis)

Focus and Purpose:

Long-term analysis, often referred to as process capability or process performance, provides a more realistic and comprehensive assessment of the actual daily performance of the entire production process under normal operating conditions. Its goal is to understand the consistency and quality of the parts delivered to customers, taking into account all the variables that naturally occur in a real manufacturing environment. It answers the question: What quality does the process actually deliver to the customer on a daily basis, considering all operational variables?

Methodology and Duration:

- Representative Operating Conditions: Data collection occurs over an extended period, reflecting the full spectrum of normal operating conditions. This means including different shifts, operators, material batches, and environmental conditions that would typically be encountered.

- Extended Data Collection Period: Data is collected over days, weeks, or even months to capture the full range of process variation. This longer duration ensures that all potential sources of variation have an opportunity to manifest.

- Sampling Strategy: Data is typically collected through a planned sampling strategy that ensures representativeness of the entire production period.

Methodik Und Dauer:

- Representative Operating Conditions: Data collection takes place over an extended period, reflecting the full spectrum of normal operating conditions. This means that different shifts, operators, material batches, and environmental conditions are considered, which would typically occur.

- Extended Duration of Data Collection: The data is collected over days, weeks, or even months to capture the entire spectrum of process variations. This longer period ensures that all potential causes of variations can come to light.

- Sampling Strategy: The data is usually collected as part of a planned sampling strategy that ensures the representativeness of the entire production period.

Influencing Factors:

- Consideration of All Influencing Factors: In contrast to short-term analyses, long-term studies deliberately consider and quantify both common influencing factors (inherent to the machine) and special influencing factors (attributable to external, assignable factors) that affect the process. This comprehensive consideration includes:

- Operator Dependence: Differences in setup, handling, and adjustment by different operators.

- Material Variations: Fluctuations in the properties, dimensions, or batch consistency of raw materials from different suppliers or production runs.

- Environmental Changes: Fluctuations in temperature, humidity, lighting, or other environmental conditions that can affect machine performance or material behavior.

- Machine Aging and Wear: Effects of tool wear, machine wear, and maintenance cycles over time.

- Setting Changes: Deviations that occur during routine machine settings or changeovers.

- Process Adjustments: Manual or automatic adjustments made to the process during a run.

Terminology:

- Process Capability and Performance Indices: The results are expressed using process capability indices such as (process capability) and (process capability index), which are used when the process is statistically under control. If process stability has not yet been confirmed, (process performance) and (process performance index) are used, which evaluate performance regardless of control status. These indices reflect the ability of the overall process to consistently meet customer specifications.

Practical Application:

- Ongoing Process Monitoring: Continuous tracking and ensuring that the process remains capable and stable over an extended period, detecting deviations or shifts.

- Validation of Customer Requirements: To demonstrate to customers that the production process consistently delivers products that meet their specifications under real-world conditions.

- Identification of Process Improvements: To identify the key causes of deviations within the overall process and to guide targeted improvement measures.

- Strategic Decision-Making: Provides important data for production planning, resource allocation, and strategic quality decisions.

Summary:

In summary, both short-term and long-term analyses are indispensable tools in quality management. Short-term studies provide insights into the fundamental capabilities of equipment, while long-term studies offer a holistic overview of the actual performance of the process. By using both approaches, companies can not only ensure that their machines are capable but also guarantee that their entire production process consistently meets and exceeds customer expectations.

Consider it this way: Before you can trust the results of your process (PFU), you must first trust your equipment (MFU).