Independent measurements

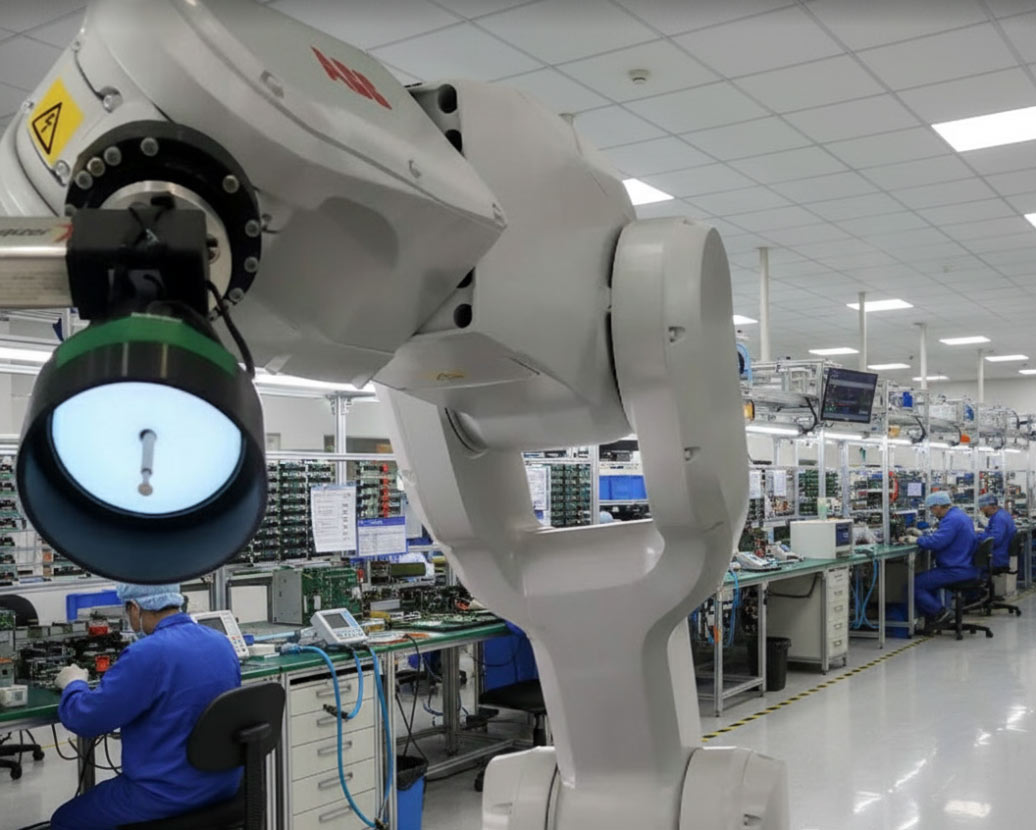

Objective, cross-manufacturer machine capability studies (MCS) for all SMT systems – we measure directly in your production facility with our mobile measuring system. You do not need your own measuring technology. Note: External support (e.g., supplier, process engineer, manufacturer, maintenance technician) is required for the operation of the machines.

Accredited testing laboratory

We are accredited according to DIN ISO EN 17025 for the determination of positioning accuracy and registered with DAkkS under the registration number D-PL-20318-01-00. Our measurements meet, among other things, the IATF 16949 requirements and provide independent analyses – regardless of the brand of the tested machine.

Fast optimization

Thanks to many years of experience, our engineers immediately recognize the causes of specification violations. 90% of the causes are systematic errors, which can usually be corrected directly on site together with your technicians. The success of corrections is always confirmed with a measurement and documented in the report.

Why an MCS as a service pays off for you

We offer you manufacturer-independent and competent machine capability studies as a service. For the investigation of the positioning accuracy of SMT systems, we are accredited according to DIN ISO EN 17025 and registered with the DAkkS under the registration number D-PL-20318-01-00.

This means that we meet the requirements for our customers who, for example, work according to IATF 16949.

In addition, we are ISO 9001 certified. What this means for you:

Measurement services in SMT manufacturing

Modular services for maximum process reliability

Answers to typical practical questions – understandable and to the point.

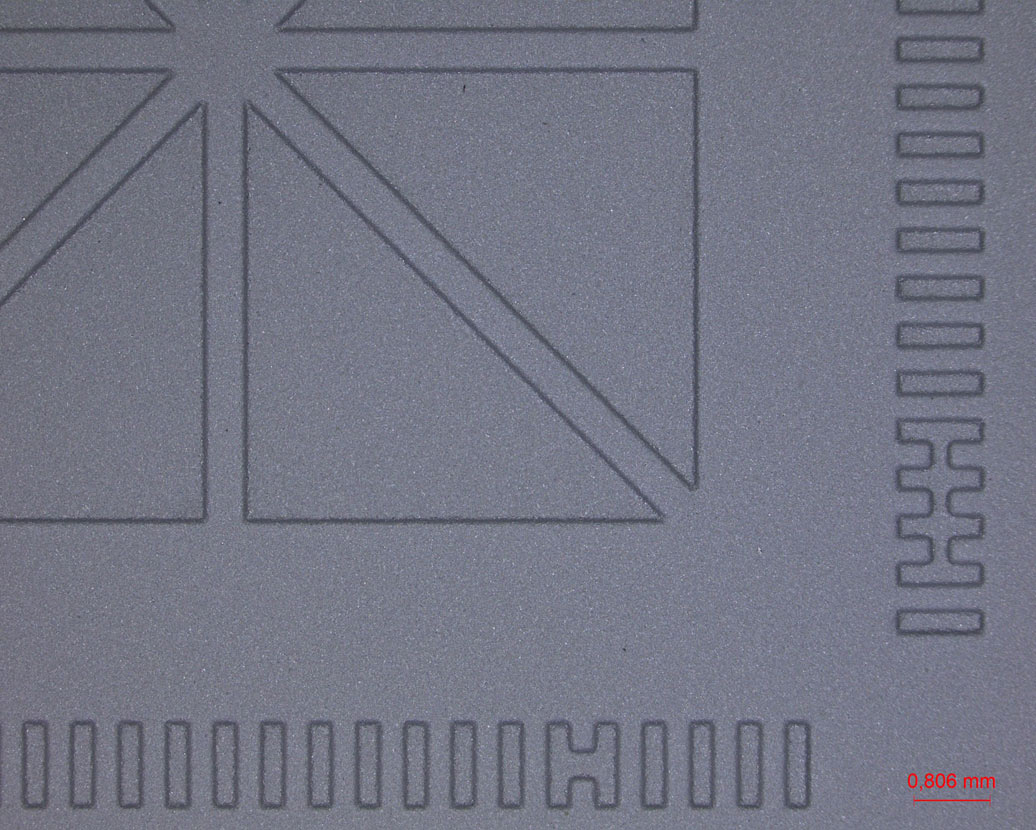

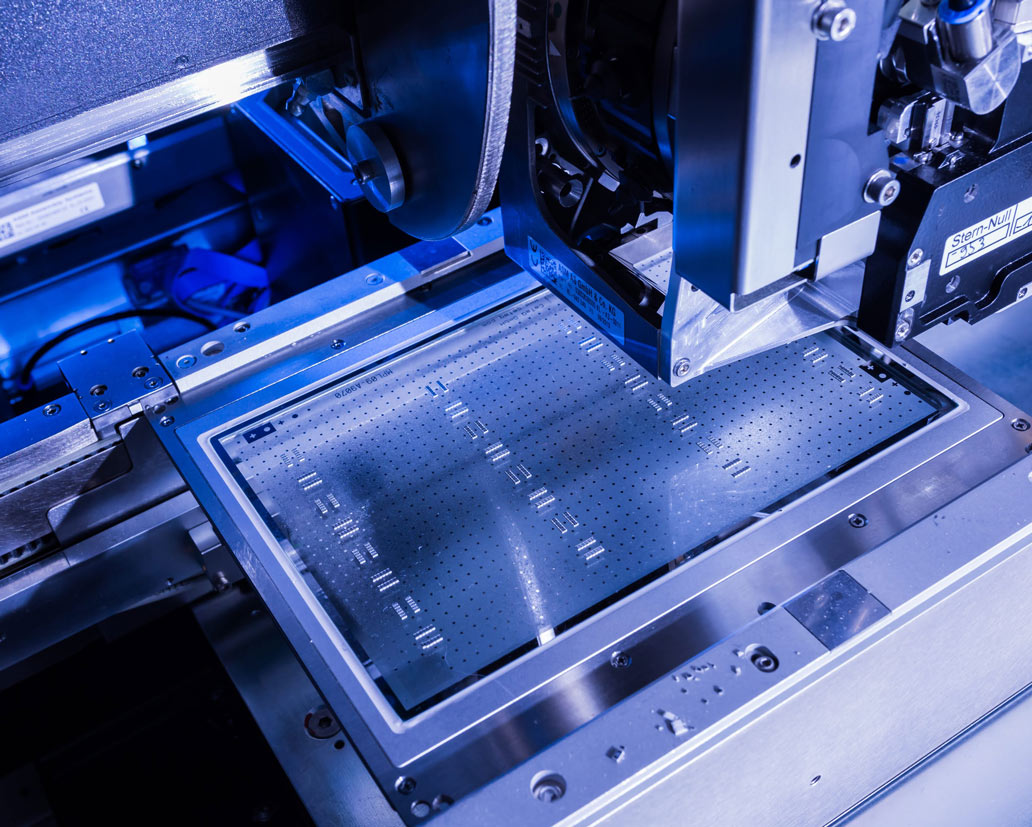

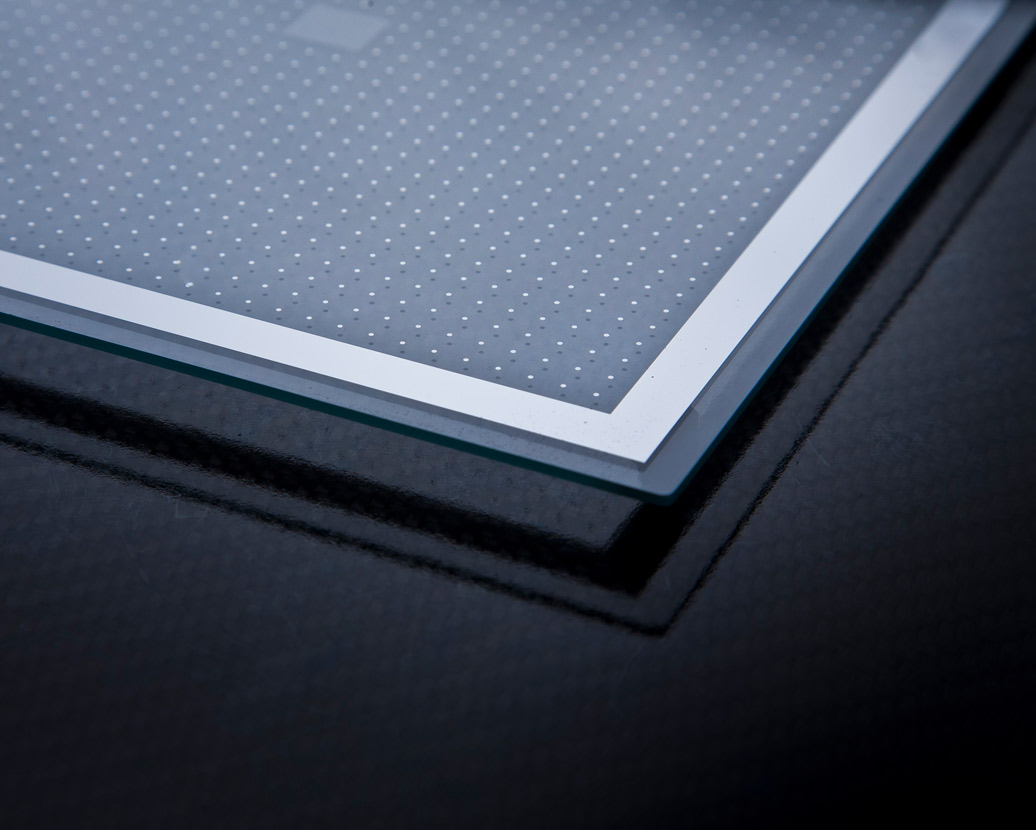

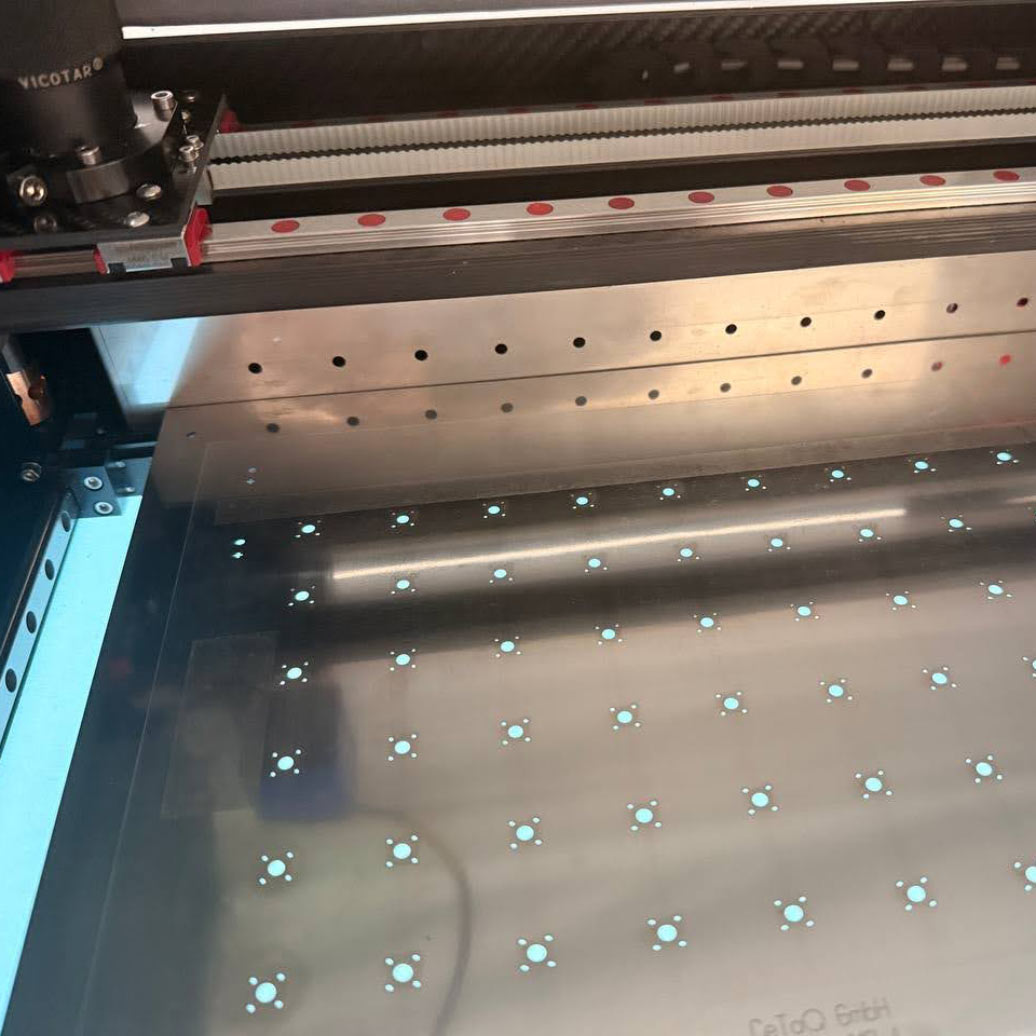

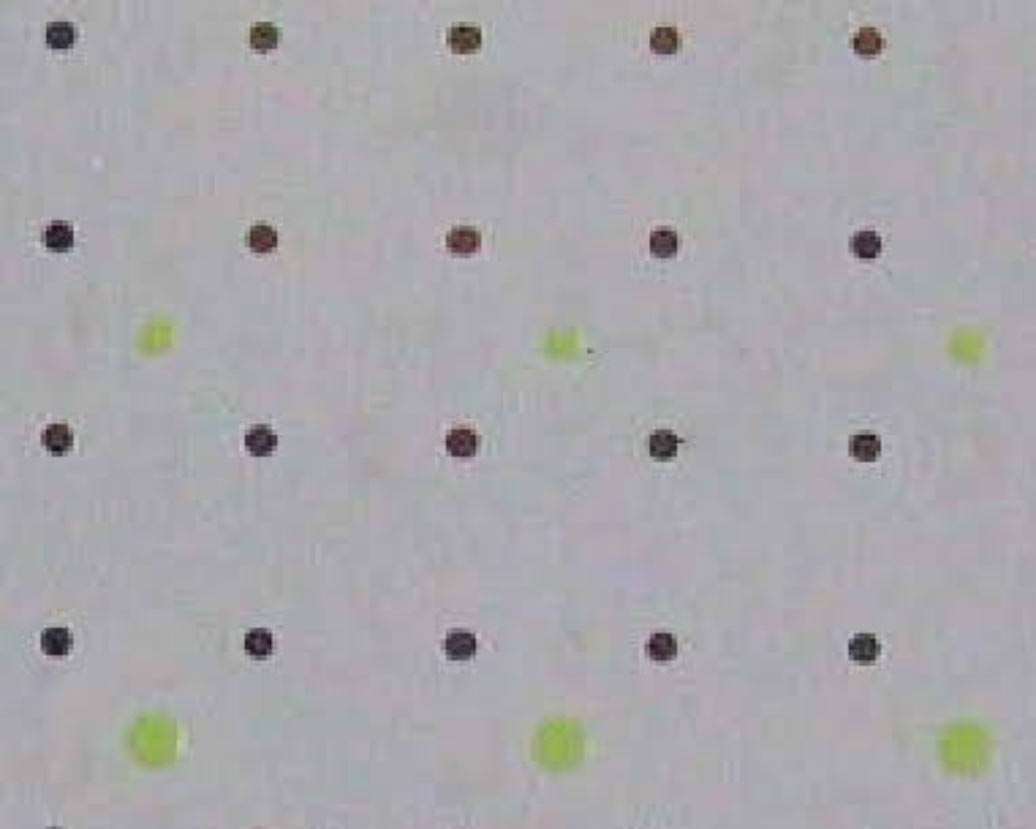

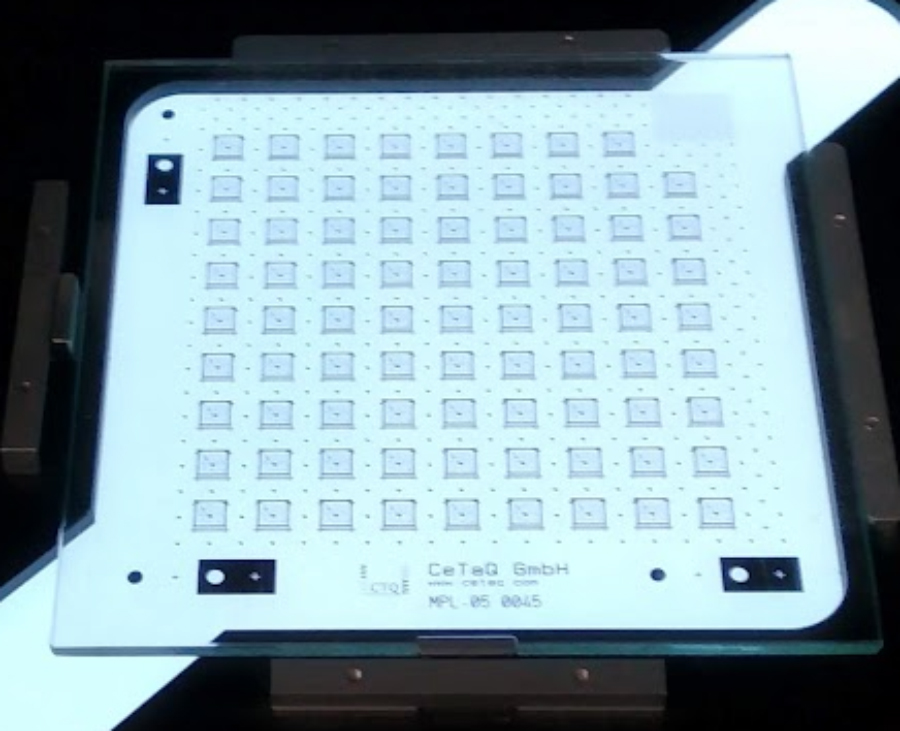

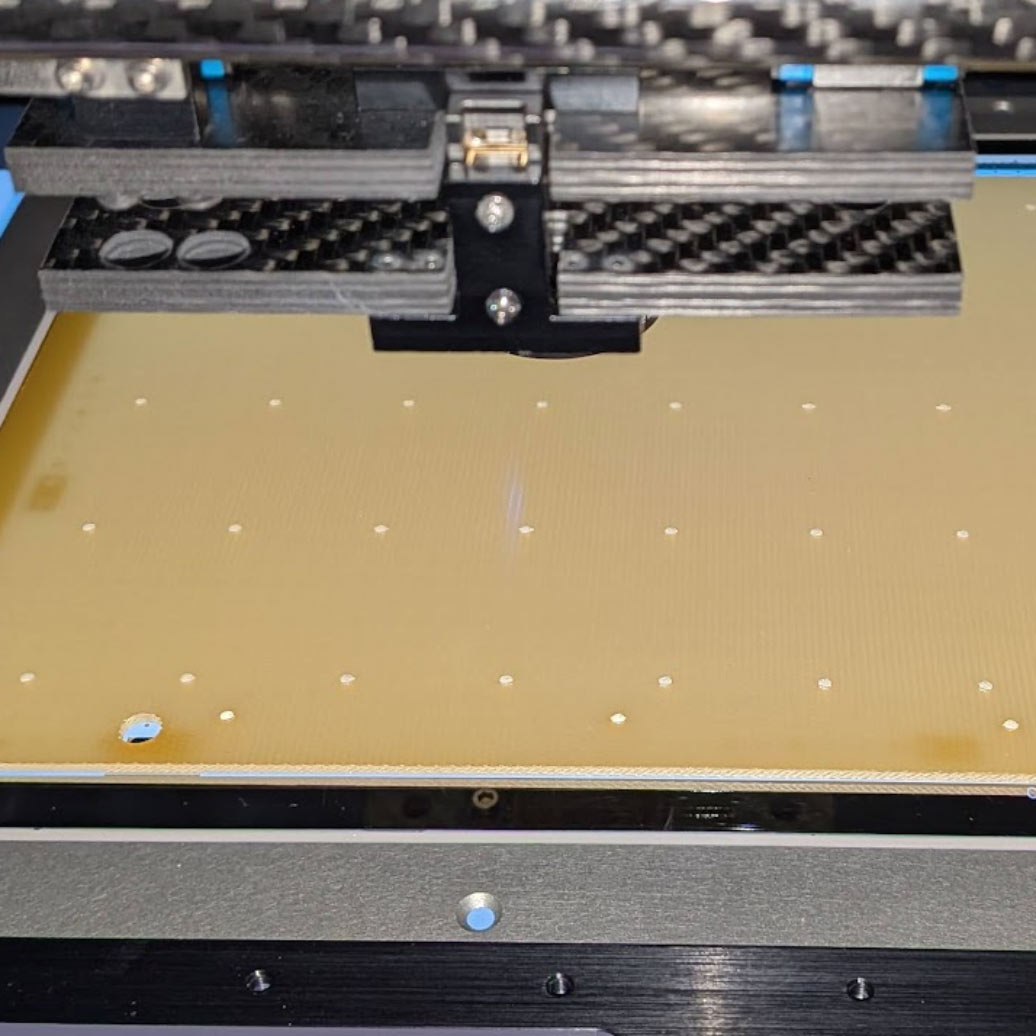

For the measurement of positioning accuracy, we use high-precision measuring plates and components. These are processed by the system under test according to the specified program. The processing result is then measured and evaluated using our systems.

The system to be tested processes a CeTaQ sensor board as in normal production. The forces are recorded during the entire processing. Our software automatically assigns these to the tools. This enables a detailed analysis and potential for improvement can be identified.

A machine capability study identifies weaknesses before they lead to rejects or customer complaints. It provides objective data that can be used to improve machine parameters in a targeted manner. This allows you to increase quality, avoid unnecessary downtime, and secure yourself against auditors or customers in a well-founded manner. A real competitive advantage, especially for IATF- or ISO-certified companies.