Measure accuracy, stability, and squeegee force – simultaneously with one device.

Precisely record accuracy and force profiles – making quality measurable

Solder paste printing is the first and crucial step in SMT manufacturing – and thus decisive for the quality of all subsequent processes. Even the smallest deviations can have significant impacts and lead to costly errors.

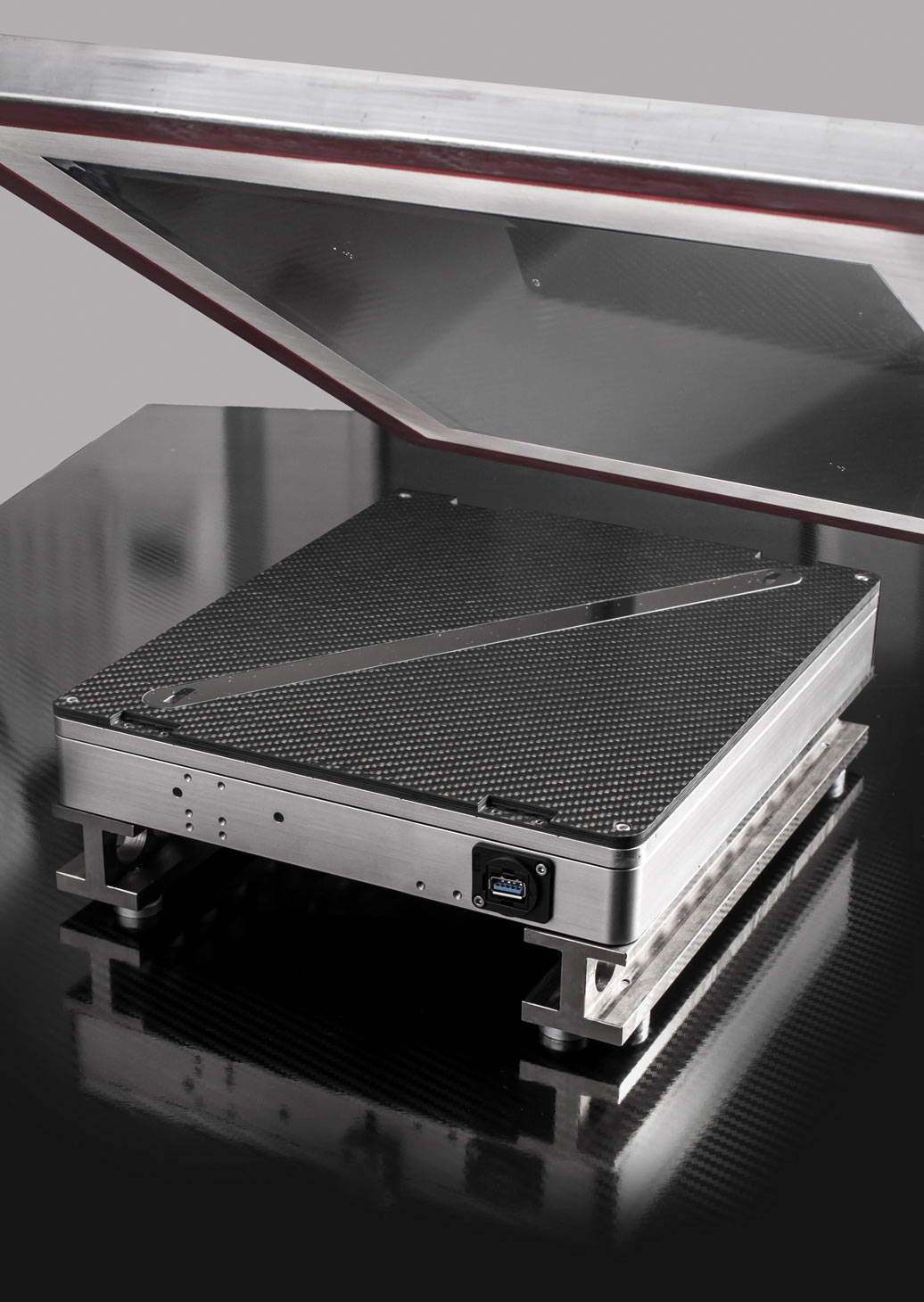

With CmPrint, a complete solution is available to measure accuracy, stability, and squeegee force. This allows weaknesses to be identified early, processes to be optimized sustainably, and quality to be secured long-term.

Tailored tests for stable printing processes

Quickly find errors, optimize processes, master audits

Technical details easily explained

Yes – a calibration with a reference plate confirms that CmPrint 2.0 Expert meets the requirements for measurement accuracy and reproducibility.

CmPrint 2.0 Expert measures multiple times per squeegee cycle, revealing movements between the PCB and stencil, such as those caused by table tilting or angular instabilities.

Highly – because even a rotation of 0.01° on a printed circuit board (~ 205 × 187 mm) can lead to an offset of 18 µm (x) and 16 µm (y) – at all corners of the board.

They provide clear statements on:

-

Accuracy (Offsets in x, y, and Theta)

-

Stability (Repeatability)

-

Squeegee forces and their distribution across the print area

CmPrint 2.0 Expert offers a complete, dynamic diagnosis: It measures accuracy, stability, and squeegee forces in a single process – without printing medium and without operator influence.

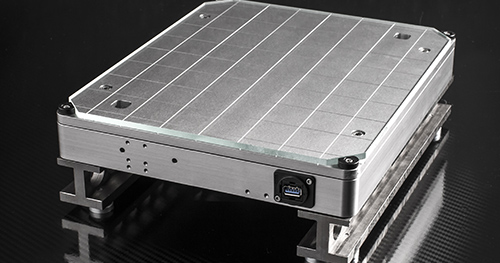

With CmPrint 2.0 Basic, forces and pressure profiles during squeegee operation are precisely recorded. The measurement data indicates whether the set squeegee force is maintained or if deviations are present. This prevents quality issues, and maintenance or calibration requirements can be clearly identified.