From machine capability analyses to process optimization: Discover our systems for maximum manufacturing quality.

CmController 9

The centerpiece for precise machine capability analyses in SMT processes – flexible, reliable, and audit-proven.

Measures accuracy, repeatability, and process stability

Manufacturer-independent and directly applicable in the production environment

Detailed evaluations for targeted process optimizations

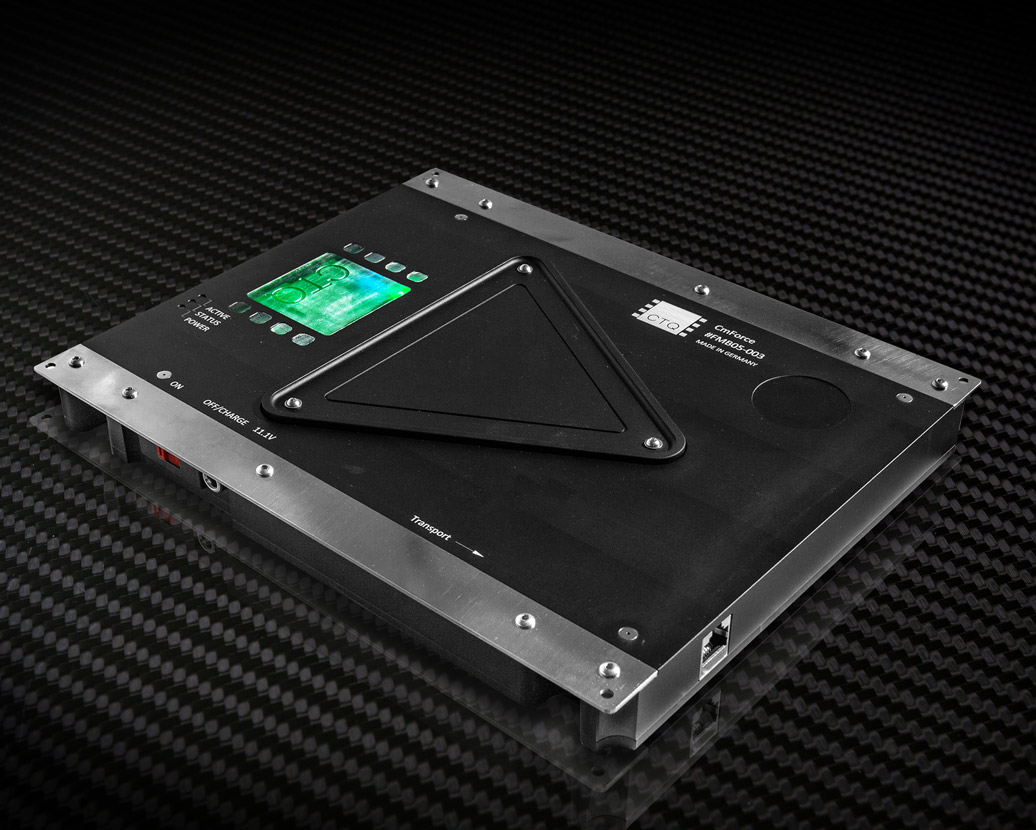

CMForce

Force measuring device for placement – measures forces directly in the production environment.

Acquisition of real placement forces under production conditions

Supports error analysis and process optimization

Usable with all common placement systems

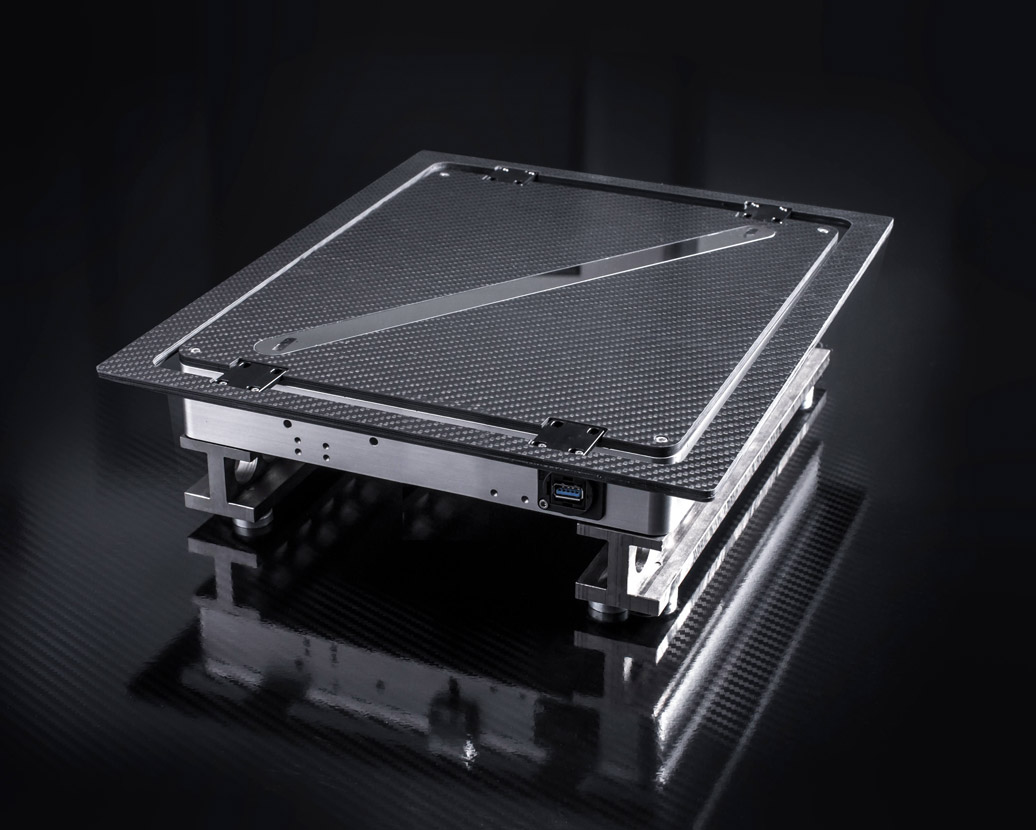

CmPrint 2.0

Efficient system for simultaneous measurement of positioning accuracy and squeegee force during paste printing.

Simultaneous determination of positioning accuracy and squeegee force

Compact and easy to handle

Optimal for process optimization

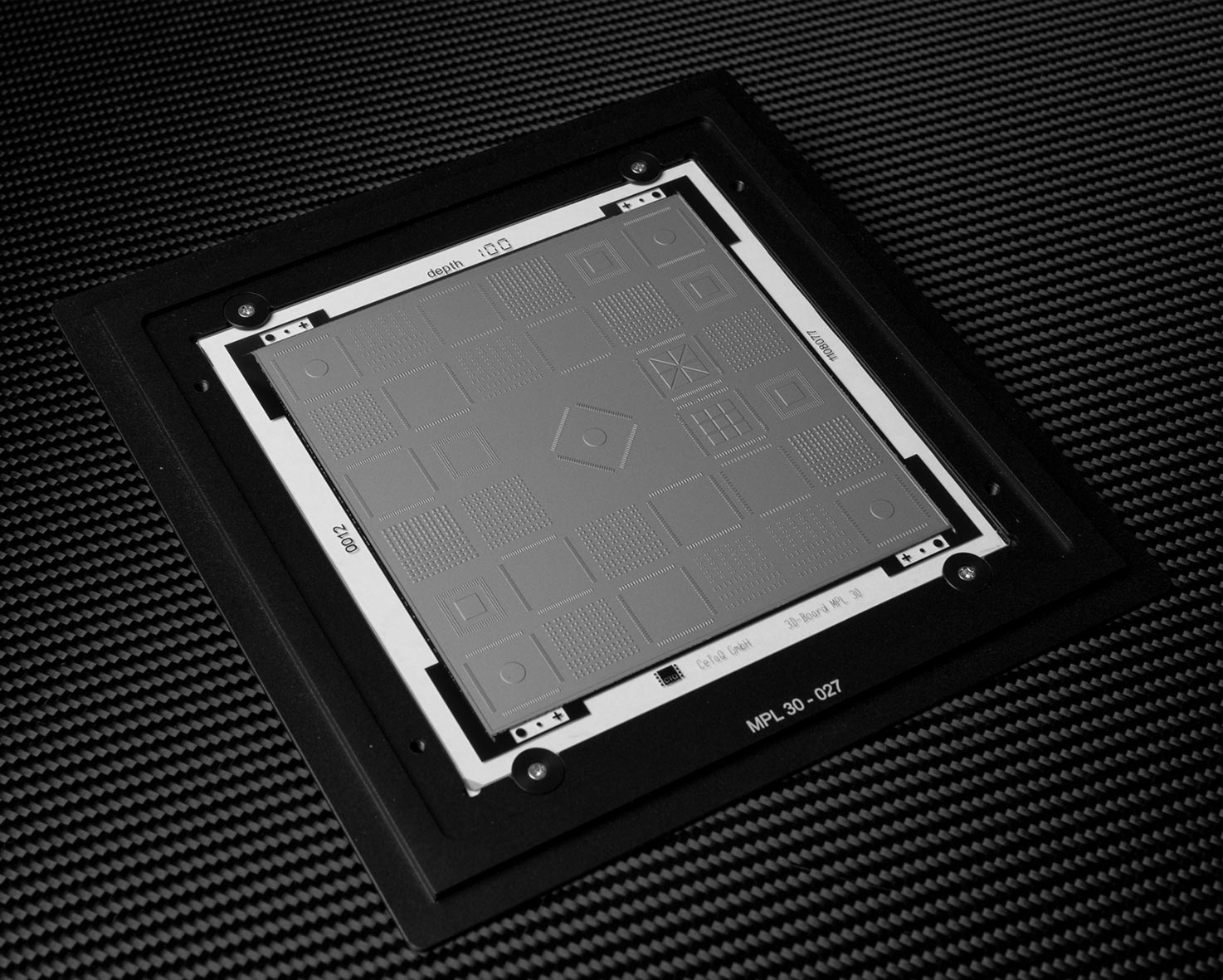

3D-SPI Board

Reference board for 3D-SPI systems with realistic SMT structures.

Covers various pad geometries and heights

Simulates typical defect patterns for SPI comparisons

Manufactured from high-precision glass

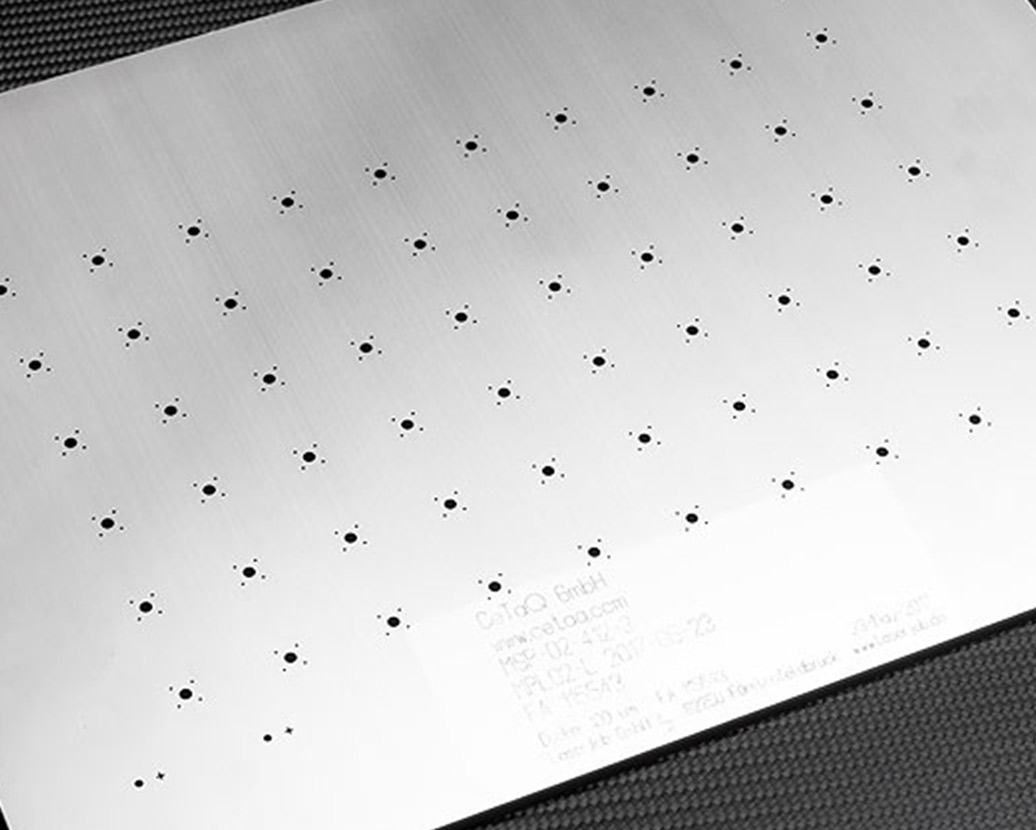

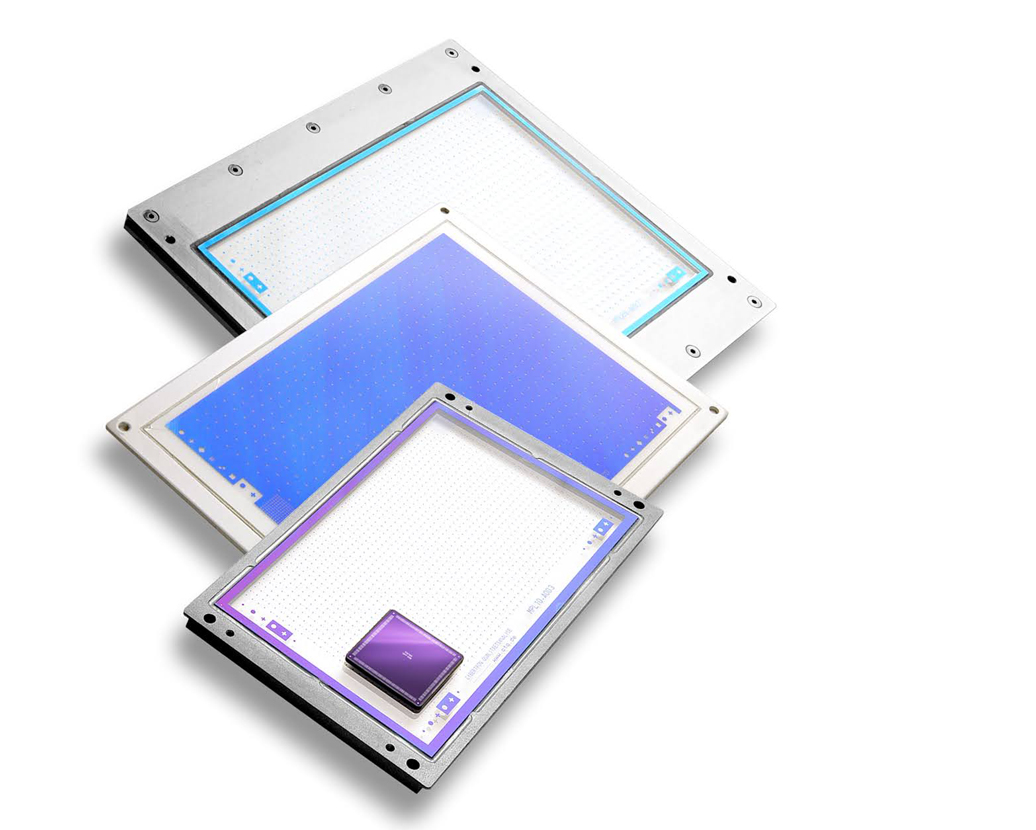

Measurement Plates & Measurement Components

Glass-based reference components for process control and calibration in SMT manufacturing.

Processed like standard components

Robust design for high durability

Calibratable

Secure precision in your production now

Achieve exact measurements and increase your process quality – start now.